I am going to go out on a limb and guess your machine is not mechanically capable of .0x resolution. The nozzle is probably dragging on the previous layer. If you can print things at .2 and they print fine then your issue is you are trying to make your machine do something it can not physically do or is not properly calibrated to do if the manufacture "Claims " it can.

The problem is not mechanical, and I'm not hoping to print at such high resolution ( 0.0x mm ), but what is not yet clear to me, is why when setting Cura Maximum Resolution to 0.1mm (this is still a high enough resolution to me) I get ~5mm straight line segments , one after another to form a big circle, with 0.1mm resolution set in Cura I have almost no stuttering issue , but when I increase the resolution in Cura to 0.05mm or 0.01mm the stuttering issue is ruining the prints, on the curved sections only, the long straight lines are all ok.

Also something I don't know yet, will a 32bit board like MKS Base v1.3 solve those issues regarding the number of gcode lines sent by OctoPrint via USB/serial ? As I think this is the issue, the 8bit board receives to many commands in a short period of time, and can't handle processing those lines (converting them to pulses needed for all motors)

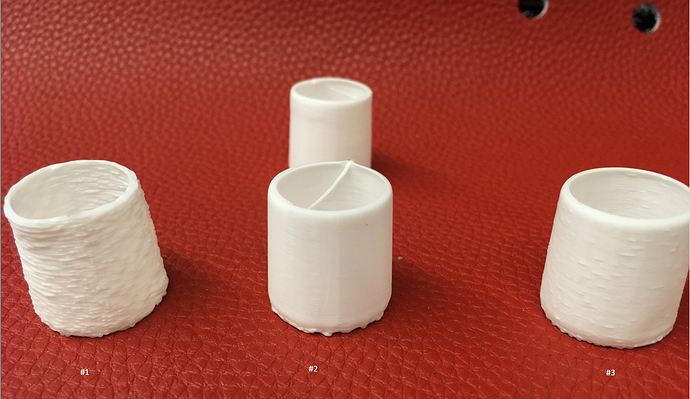

Here are some more test to show that the actual stuttering problem comes from overloading either the serial communication or Marlin firmware on a 8 bit microcontroller, and not from the resolution of the print or the speed of printing alone, those are some factors, but in the last part of the video you can see I can print well simple models with 150mm/s without any stuttering issue.

It's important to check the communication blue leds also, when resolution is high and there are many small segments, the leds are almost continuously light up. When there are some long simple segments, but at high speed, the leds bearly light up, and no stuttering issue is shown.