You are correct that the Smoothieboard does not currently support spindle synchronized motion, but that's something I'm actively working on. When I started this project, Smoothie's spindle control module didn't really work at all, but I've made headway on a few fronts:

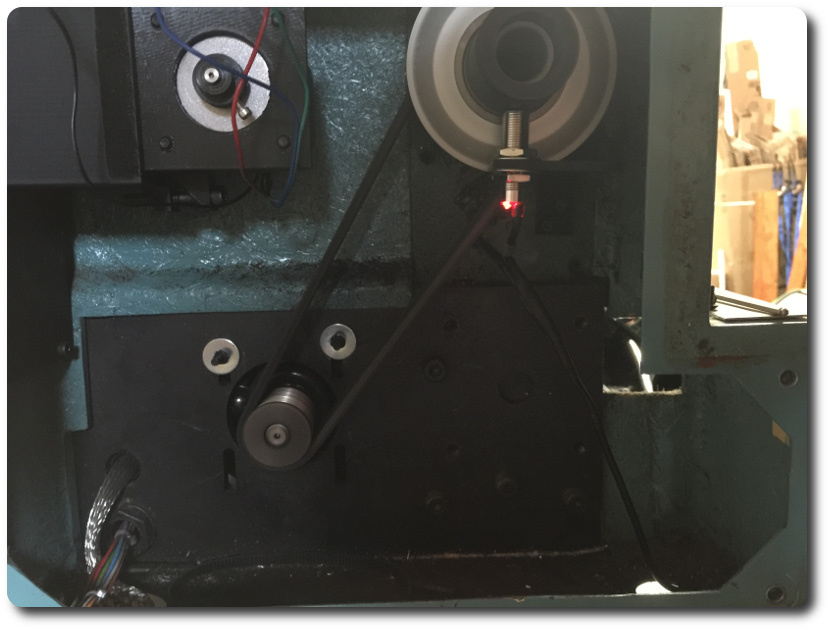

My main challenge around spindle sync on my personal machine is that I'm currently using a single magnet on the spindle with a hall-effect sensor to pick up rotations and I'm having a hell of a time getting the speed stable. At best, it wanders +/- 5% or so, with substantially worse behavior at low speeds.

http://www.wolfteck.com/2018/03/03/orac_spindle_control/

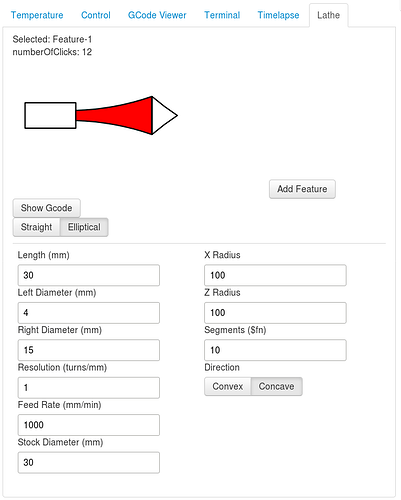

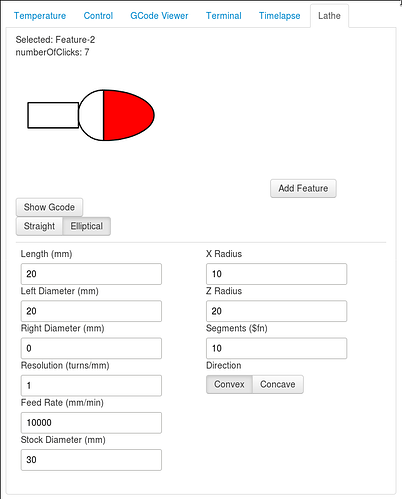

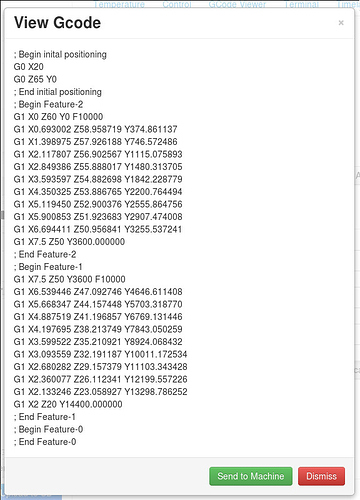

I'm eventually going to try switching over to an optical sensor on a big shutter wheel and having the Smoothie divide the signal to feed back to the tach input on the MC2100 (in addition to managing the PID side of the house), but I've been more interested in the UX side of things the last couple weeks.

If that doesn't work, I'll probably wind up biting the bullet and going back to AC with a VFD where the speed you ask for is the speed you get, full stop.

For synchronized motion in the mean-time, I've cobbled a NEMA34 stepper inside the headstock, so with a belt swap, I have reasonably precise, albeit relatively low torque spindle synced motion control.

As for LinuxCNC, I checked it out, yes. If I was running a pro shop, that's probably the direction I would go. That said, I have a different set of goals for this project. My main goal is for civilians (as opposed to machinists or *nix aficionados) who visit my garage to come away thinking "I could do that" as opposed to "damn, that's complicated".

Personally, I see LinuxCNC the same way I see dorking with kernel modules or designing parts in OpenSCAD -- fun for me to play with because I'm a giant dork who spends way too much time at a computer, but overwhelming for people who are focused outside of this niche.

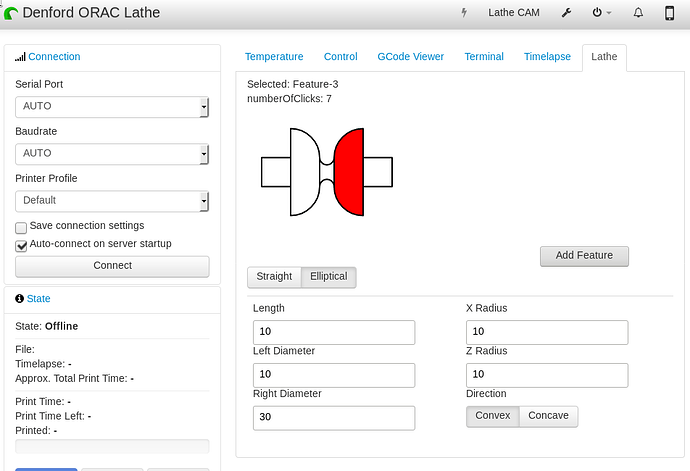

This is actually what drew me to OctoPrint in the first place. It's incredibly powerful if you really dig into it, but more importantly for my goals, it's approachable. The UX is clean and simple and folks who don't know anything about printing / machining seem to just "get it" very quickly.

That said, if you have any resources showing the user-friendly / gentle learning curve side of LinuxCNC, being closer to the project, I'd love to see them.

I certainly haven't seen OctoPrint controlling a lathe yet. Wow!

I certainly haven't seen OctoPrint controlling a lathe yet. Wow!  Thank you for sharing this!

Thank you for sharing this!

I haven't done a setup for my lathe, yet...it's still manual, but I will be CNCing it eventually. I originally got into MachineKit when I decided to CNC my mill.

I haven't done a setup for my lathe, yet...it's still manual, but I will be CNCing it eventually. I originally got into MachineKit when I decided to CNC my mill.