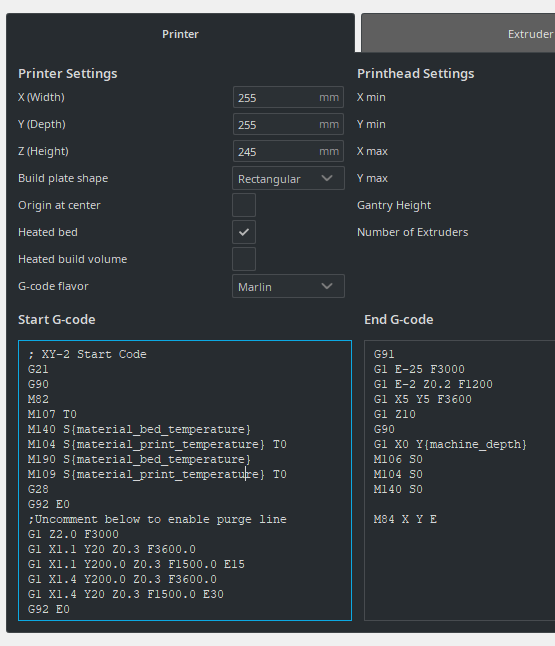

I' using this lines (inserted automatically in each .gcode-file before begin):

The relevant part here may be the 3 extrusion-lines below, I have good results with this initiation,

I'm using this with Prusa-Slicer, Cura and Simplify3D. My 3D-Printer is a CR10, modified...

;~~~~~~~~~~~~~

; Edit Temperature depending on the material:

; PLA: 200-215gC / 60 -65gC

; PETG: 230-250gC / 70-75gC

; TPU: 230gC / 60gC => half speed!

;Temp:

M104 S230 ;Set Hotend Temperature

M140 S72 ;Set Bed Temperature

M109 S240 ;Wait for Hotend Temperature

M190 S72 ;Wait for Bed Temperature

M105 ;Report Temperatures

;!!! Search further for M140 (Bed Temp), M104 (Extruder Temp.) and M106 (Fan) !!!

;~~~~~~~~~~~~~~~~~~

M82 ;absolute extrusion mode

M201 X500.00 Y500.00 Z100.00 E5000.00 ;Setup machine max acceleration

M203 X500.00 Y500.00 Z10.00 E50.00 ;Setup machine max feedrate

M204 P500.00 R1000.00 T500.00 ;Setup Print/Retract/Travel acceleration

M205 X8.00 Y8.00 Z0.40 E5.00 ;Setup Jerk

M220 S100 ;Reset Feedrate

M221 S100 ;Reset Flowrate

M420 S1 ; enable the leveling mesh that previously was aquired with M29 and saved with M500

G28 ;XYZ-Homing (w. BLTouch)

;Draw 3 Extrusion-Lines and press Filament-Rests to Bed:

;G28 ends with Z=20mm, so Nozzle is on 20mm (height)

G92 E0 ;Reset Extruder (to "0")

G1 X110.0 Y10.0 F8000 ;Move fast to first position (X110,Y10) with 8000mm/m ("X,Y-Zero" is at 10,10 mm from "0,0")

G1 Z0.25 ;Move Down Z-Axis(=Nozzle) to 0,25mm height from bed

G1 X10 Y10 Z0.25 F1200 E10 ;Draw the first line (100mm length) in X-direction "0") with 1500mm/m extruding 10mm

G1 X10 Y15 Z10 F3000 ;Move Y+5mm forward and Z+10mm up

G1 Z0.25 ;There Move Nozzle down to 0,25mm...

G1 X60 Y15 F1200 E15 ;...and draw the second line (50mm) in X-Plus-direction, extruding 5mm more

G1 X10 Y25 Z8 F3000 ;Move to third position (Y+10mm and Z=8mm height)

G1 Z0.25 ;there again move Nozzle down to 0,25mm

G1 X10 Y75 F1200 E20 ;...and draw the third line, now 50mm in Y-direction

G1 X10 Y80 Z6 ;finally move Nozzle to Y+5mm forward and up 6mm (height)

G92 E0 ;Reset Extruder (Extruder-relative-position to "0")

;~~~~~~~~

;gcode at end-of-file:

G91 ;Relative positioning

G1 E-2 F2700 ;Retract a bit

G1 E-10 Z0.2 F2400 ;Retract and raise Z

G1 X5 Y5 F3000 ;Wipe out

G1 Z10 ;Raise Z more

G90 ;Absolute positionning

G1 X10 Y270 ;Present print

;G1 X10 Y10 ;To Home-Position

M106 S0 ;Turn-off fan

M104 S0 ;Turn-off hotend

M140 S0 ;Turn-off bed

M84 ;Disable all steppers

M82 ;absolute extrusion mode

;End of Gcode

;~~~~~~~~~~~~~~

;for my prusa-slicer in conjuction with "DisplayLayerProgress-Plugin":

;gcode before each layer-change:

;Layer: [layer_num] / Z: [layer_z]mm

M117 INDICATOR-Layer[layer_num]