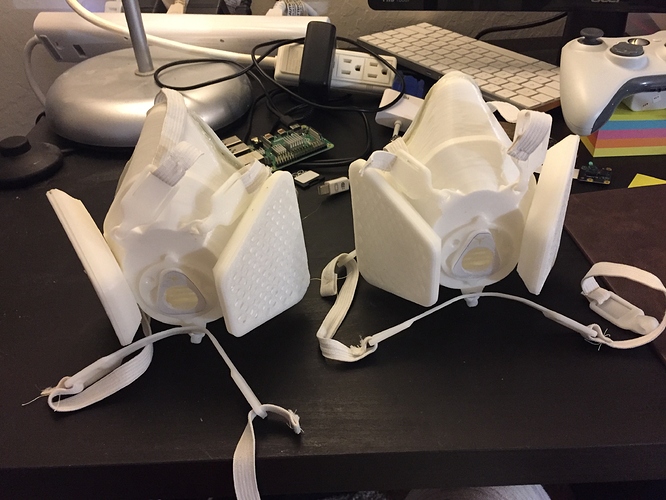

It literally took many days (a week?) to finish two of these. The main mask part itself probably took ten hours alone. Had to make some modifications: 1) the flaps + pins just don't work, use post-consumer plastic packaging and just cut to fit; 2) the suggestion to use Superglue is insane, again just use hot glue. The instructions truly are a nightmare. Make sure to go back to their website and see some of the photos for a chance of figuring this out. Unlike the instructions, I would suggest adding the elastic first and use a sewing machine to make things neat before any bending and installation of the strap ends.

I tried this one and it seems to be quite nice.

I have to tune my tpu/flexible settings further though.

Just fyi - you don't need a heated bed for tpu

That one is cool. The one I did claims to be the only one that's FDA-approved, believe it or not, which is one of the reasons I did them.

Honestly, if you could get a partial print of the mask part itself so that the flexible filament is the bottom third, that might be the best hybrid. You need the rigidity for everything that mounts to it but you need it to flex at your face.

Next testprint I'll try a filament change to pla midprint.

Let's see how that works out

With the flexible stuff, I had to increase feed rate to maybe 106% or somewhere in that range.

It depends on the type of tpu

Like this one

varioShore TPU allows users to vary the density of the material by adjusting temperature and material throughput (speed & layerheight). At temperatures between 200 and 250C the materials will start to expand to roughly 1.4-1.6 times its original volume. This means the material can be printed at low flow rates (60-70%), to compensate the active foaming, which in return gives very soft printed parts. Between 190-200C the material can be printed without foaming, resulting in different haptics and harder prints compared to foamed samples.

I got that and this

in my "quarantine corner" where I keep packages for a few days.

Oh... and I found it to be damned difficult to remove the flexible filament from any of my beds. I had to print a layer of PLA then switch to the flexible stuff on the second layer.