I started on 3D printing by ordering a BuildOne. It's still on order. Actually, two on order. I guess I went double or nothing.

So I bought a 'used' Anet E10. That was my first actual printer. I've spent a lot of time fixing it. I fixed and then replaced the heated bed, I changed the carriage/extruder to use the HEVO mount with a custom carriage that adapts to it. I'm still working on the carriage to make it fit just right; my current one is too high, so I have trouble adjusting it against the bed. And about every other time I modify it I have to make a new Z stop. But it's a PITA in other ways- I can't get the X/Z arm to be level. Sigh.

I recently decided to step up and order a Prusa. I'm tired of fussing with bed leveling, and the 'crash detection' will be nice, among other things. Those are backordered, but mine was slated to ship in early/mid July. I emailed them a week or so ago and asked 'em to change from the powdercoated bed to the PEI bed. I'll just pay for the powdercoated one later, since they seem to be having lots of production issues with them.

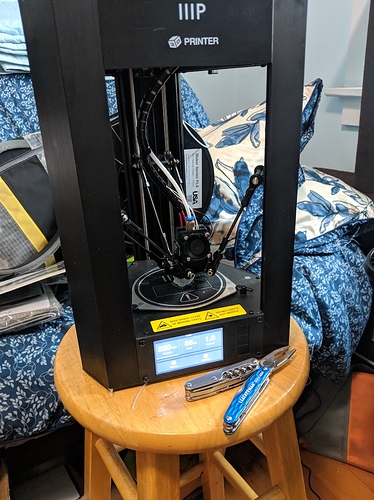

So last night I bought a Monoprice Mini Delta. It's pretty much the only 'basic' printer that has the features I can't live without: bed level sensor, heated bed. I figured it'd be good for helping me print parts for my E10 until the Prusa comes.

Aaaand about an hour later I got an email saying my Prusa shipped. Monoprice doesn't really cancel orders, so I guess I'll have about 2.1 working printers very soon.

Just wanted to share.

Don't get me started. ha

Bought a Robo C2 printer almost exactly a year ago. I immediately noticed a variety of what are in highsight design flaws.

- The location of the spool holder on the back is too high to create a useful angle to the filament sensor block, not to mention that a 1KG spool would often just fall off mid-print, resulting in a failed job [I've designed two different series of filament spoolers to replace the stock version]

- Out of the box, the power switch was backwards (OFF=ON)

- The bed design is basically a diving board which bounces on the front, leading to z-related banding for parts the closer they are to the front [designed and installed a cantilever stability plate which attaches under the bed]

- The filament runout switch is completely dysfunctional in both design and functionality and I've lost perhaps ten jobs from this already; it only has one micro switch rather than the expected two [I've designed/printed the replacement but haven't installed it yet]

- The unheated bed without modifications has a difficult time with first-layer adhesion, especially with the stock tape square, as supplied [replaced with BuildTak, added insulation around the printer]

- The stock power adapter was 19V and with barely enough power to manage the power needs [replaced with a beefy 24V brick]

- The software provided by Robo 3D (although pretty) isn't updated fast enough to merit my confidence [I've replaced all of their code completely, to include their version of Cura]

- Robo's iOS app was more pretty than useful [I wrote a replacement multi-platform smartphone app]

I've had my share of frustrations with my print jobs. Off-brand filament will bind in the PTFE tubes so I'll have to "work around" that with some ad hoc solution in the moment. I probably need to print something to keep the filament dry. Having just replaced the nozzle, I find that I now need to bump the temperatures by 5 degrees to get the plastic to keep flowing. Before doing so, it wouldn't be unusual to come back from a coffee break to find it "air printing" a half inch above the last consistent layer.

I should try to print the very first part I tried to do one year ago (the reason I bought the printer in the first place). Back then, it would curl in the corners so badly that it wasn't funny. But I've solved a lot of problems since then. Maybe it will work this time.

I'd love to design a printer based on all my experiences. I have a feeling that I could make a more functional one than this.

Both the MP Mini Delta and the Prusa MK3 (kit) arrived today. The Delta came first and is preassembled, so .. I just did a couple of things:

- grab someone's slicer settings

- add a Pi/flash octopi

- add "Malyan/Monoprice Connection Fix" plugin so it actually connects

- fiddle with the filament/hotend for a few minutes because it wasn't extruding

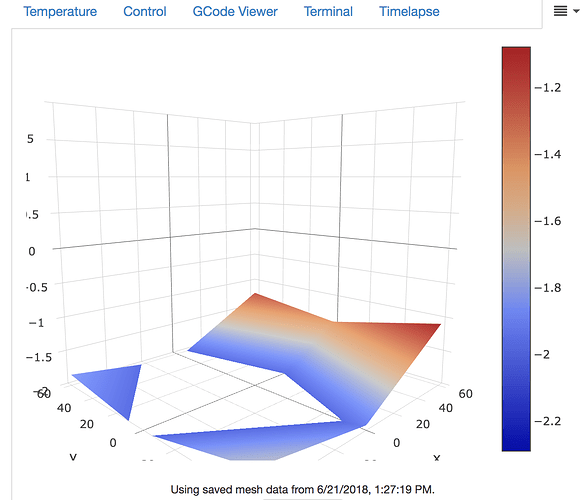

- add Bed Visualizer plugin for fun

I had it running within an hour. It's smaller and noisier than I expected, but not bad on both fronts. I'll probably do something different for the power supply so I can power the Pi and the printer together and use the Pi to control the noisy fan in the base.

1 Like