In my opinion the 3d printing technology has come far enough (and is cheap enough) that we can now build a commercial-level print farm for not a lot of money. Yes, there are those who already have farms. And yes, they are successful. But most of the examples I've seen require a couple of things.

Usually, a human must attend to every printer. Need more printers? Need more humans. Want to sleep and still print parts? Need more humans. Want to focus on marketing or CAD work? Need more humans. Unfortunately, the Cost vs. Scale vs. Time will get you in the end.

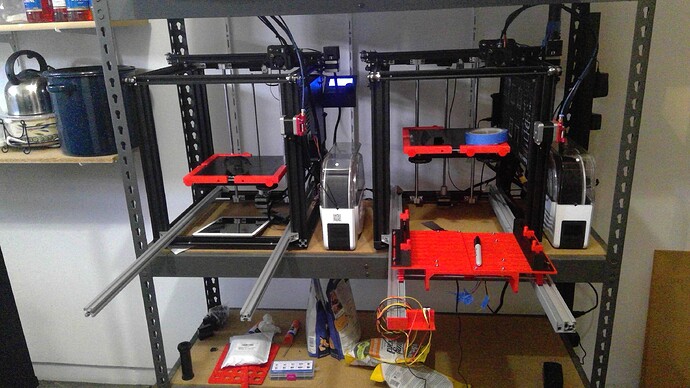

Next, get expensive commercial printers. No, expensive is not going to work. We need to use the same sub-$400 printers that most of us already have. In the hands of skilled makers, they print just fine. This has been proven.

And, profit margins will shrink as the printing industry matures. We need to bake that eventuality into the project from the very beginning.

Lastly, it has to use OctoPrint. Obviously.

Soooo.... apparently we need to automate the *&^% out of this project.

And it has to start out in a garage. All the best projects start in garages. Everyone knows this. It's science.

We have the capability to make the world's best 3d printing solution. Probably Better than before. Probably intelligent. Better , stronger , faster .

Some thoughts:

To solve the human issue, we could use one of those industrial robot arms to drive around and attend to the printers. But those are a lot of coin. We don't have a lot of coin. And we are keeping in mind shrinking profit margins. So let's do this with only a little coin.

We could use one of those solutions where the part gets scraped off the bed and falls into a bin on the floor. But then what do you do when you're printing delicate parts? Back to humans. Or maybe we just think that dropping all the parts on the floor is lame? OK. So let's load and unload the print bed somehow - like real production line manufactures do it. Like pick and place automated processing.

And of course we will want to queue up the print jobs and walk away.

I think we have a framework now. Let's recap:

- Load and unload the print bed automagically

- Queue up the print jobs

- Monitor and track all the printers and jobs so that the workflow never stops (except for repairs or filament changes - stuff like that)

- Repeat

- Do it so well that only 1-3 people can run a ton of printers

- Re use what already exists if possible. Plugins, thingiverse parts...

- Print anything and everything possible. After all, that's what we do. We print stuff.

By now, you may have guessed that I have a few ideas and probably a prototype in progress. hehe

I'll add to this thread over time so you can follow along. Looking forward to the conversations on this journey.

It's gonna be pretty fun.