At my shift last evening at school, I decided to prove to my students that 3D printers are useful so I wanted to fix the refrigerator in the time remaining. The refrigerator at this venue has been wonky; it's missing some sort of internal spring on the water-dispensing tab that would return it to the OFF position once pressed. The result is that every new student ends up spilling a lot of water on the floor when they are initiated into this fact.

So—without a digital caliper—I managed to design a part, slice it using an unfamiliar slicer, print it and put it into service. It finished within five minutes of the end of my shift and amazingly, it worked perfectly.

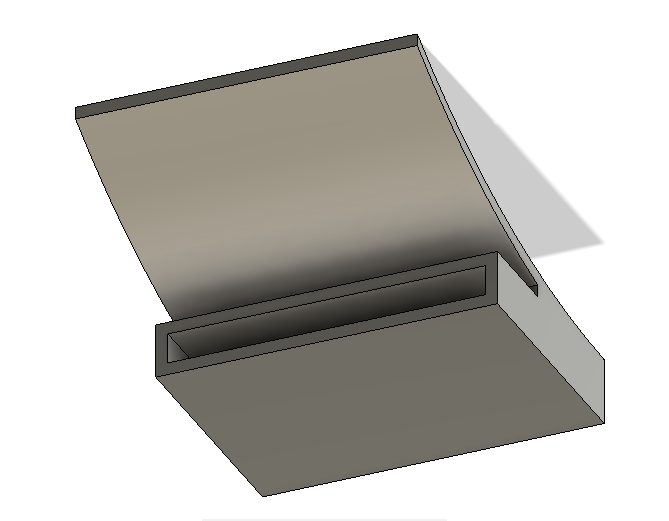

What "measurements" I was able to make were accomplished by using a spare Scrabble tile that I'd printed earlier (and I knew the accurate dimensions for that). I just estimated using that as a ruler, if you will. I had to design in the appropriate spring pressure to both hold it on and to counteract the sensor's piston or whatever was back there. I oriented it sideways on the assumption that the printer would be okay bridging the roof at a 5mm gap and that turned out perfectly (versus running the tab straight up).

Slicer: FlashPrint

Printer: Flashforge Creator Pro

Filament: PLA

Print orientation: sideways