Losing steps on one axis need not necessarily be caused by the common issues like a loose pulley, poor belt tension or an overheated driver ...

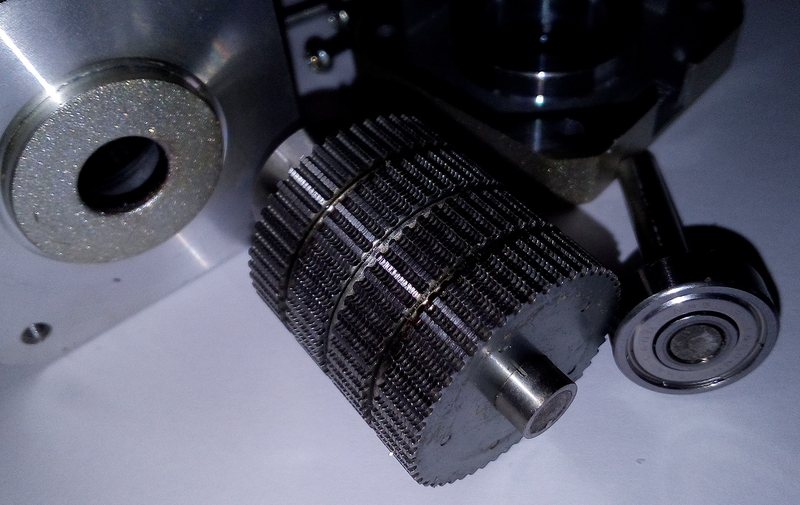

Hold on for a sec now...... is that a cracked stepper shaft ?????

Jan

Yepp, it is sheared off (is this the right word? in German "abgeschert").

O.k. the printer has around 7000 operating hours ...

Yes, right word.... on the surface, do you see any signs of corrosion which could indicate a pre existing crack from manufacturing or transport damage ? I can NOT imagine a 3D printer having so much fore exerted to shear of a shaft that size, the stepper itself would neither have the drive torque nor the holding torque to do such damage.

Jan

Regarding the force or torque I go absolutely confirm with you.

The only thing I can imagine is a little crack during production that became wider and wider with the time.

On the rotor side the shaft has a 6.5mm diameter while the shaft itself has 5mm and exactly at this point where the diameter changes it's sheared off.

Until the moment I noticed the reason for this error I tought I have already seen everything what can happen in 3D-printing

Sounds like a milling error to me.

That's crazy! What lead you to determine this was the problem? The motor just wasn't turning?

First symptom was the printbed didn't move as it should - in hindsight crazy, but it still moved sometime a bit.

First tought: a loose pulley - nope.

Removed the belt and the pulley and spin the axle by hand - but most time of a turn - was missing the normal resistance you feel when you spin a steppers axle.

So I decided to open the stepper and have a closer look ...