I see. The mesh direction is accurate and I can use it to make manual corrections. The angle corrections cannot be flipped. In any case I can just use those by adjusting the orientation mentally, or simply do iterative corrections manually.

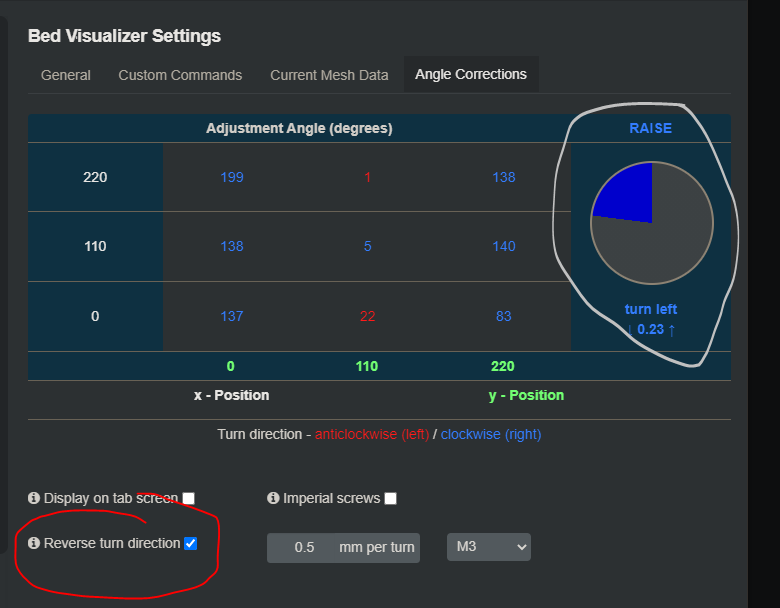

The option you're looking for is 'Reverse turn direction. Heads up as it won't change the 'Turn direction' text at the bottom, but it will change the text below the circle

Oh I see I'll try it. Thanks.

sidenote, if you mean the 0 -> 220 point labels on the chart, I had to use 'Descending y axis' on the 'Current Mesh Data' tab to get them to look like it does below on both charts

220

110

0

0 110 220

Yes that's what I mean. Thank you.

That worked. I'm also having issues similar to yours. I'm wondering if the correction is actually being applied. I'm still printing with adjusting the bed as flat as possible manually. Also the glass bed in my case is being warped by too tight clips. However I believe it should be able to correct for a warped bed.

I generally don't save settings in my startup. Also in testing if you do a G29 in your startup, the leveling is automatically on. So if doing the leveling for every print, you could just leave off the M500, and the M420 commands.

As to the z fade, you are correct. it gradually changes the impact of unlevelness in however many layers you specify. If M420 Z is not set, then it just follows the bed contours for the whole print.

It is always a good thing to try to get your bed as level as possible before the leveling. I have a CR10 clone that goes wonky once in a while and the left side goes way out. I see in your numbers you have a layer height difference between your center and one corner. So getting the bed corners at the same height will minimize the "tilt". ABL fixes lots of things but seem to struggle on the stuff that is way out. Some of the variance you see could be your ABL sensor. There is a calibration test that you can run (it may have to be enabled in the firmware) Take a look at the M48 command. It does a probe accuracy test.

I did a M503 and saw everything is running fine and the results reflect that. If anything it was my fault when I set "set origin at center" and "set relative positions". Reverting yielded a very interesting first bed probing result where it looked like there was a "black hole" in the center of the bed. It corrected on the second probing. It was actually pretty funny! Amazing plugin!

Thanks, I appreciate it.

Question: after running the above GCODE should I add an M500 to store the bed level data for next session (restart of printer)?

Yes, if you have EEPROM enabled that's not a bad idea.

Hello. New to Octoprint. I read the instructions above but I am somewhat lost. I have a PRUSA MK3S 320. When I try and use Octoprint, the bed seems to be unlevel. From the SD card it prints OK not great. Is there a way to use Bed Visualizer and save the results so Octoprint can make minor corrections during the print? What would you need me to do to gather information to help me figure this out? I saw mention of saving to EEprom but I have no idea how to do that. Can I add GCODE to my slicer settings to make sure the bed is level before a print? I am currently using PRUSASLICER. Any info you need, please tell me how to find it and I will promptly provide it. Thank you for any replies.

The plugin does not do that, and never unless someone forks the plugin and maintains their own branch.

In marlin, that's typically an M500 gcode command, but I'm not sure if PrusaFirmware uses the same or not.

I would think so. Adding the start gcode to run a probe I would assume would activate the leveling correction. You may want to check out this guide, which uses OctoPrint and the PrusaMeshMap plugin, might be easier to follow, although it requires the nylock mod to your bed.

I tried the nyloc bed fix and never got it right. Had to go back to factory set up.

Medic433

Hello! I just started dabbling with your bed visualizer. First off, what a fantastic plugin. I have the data, but now don't know how to apply it to my G-codes when I print. is it as simple as putting a G29 in the before print starts Gcode section? or an M500? Using a CR 6 SE

Here's what I get from running the plugin

Recv: 0 1 2 3

Recv: 0 +0.153 +0.144 +0.175 +0.150

Recv: 1 +0.062 +0.053 +0.051 +0.016

Recv: 2 -0.051 -0.065 -0.085 -0.116

Recv: 3 -0.135 -0.161 -0.181 -0.213

Recv:

Recv: echo:No EEPROM.

Recv: X:205.00 Y:30.00 Z:2.82 E:17.61 Count X:16400 Y:2400 Z:1190

Recv: echo:busy: processing

Recv: ok

Send: M155 S3

Recv: ok

Send: M500

Recv: echo:No EEPROM.

Recv: ok

Hello @Rett_Genatempo!

When you run a G29, the firmware usually takes the results on its own to optimize the first layer(s) prints.

Ewald is correct, the plugin doesn't do anything to compensate for the probed mesh, it literally just displays what the firmware sees and reports from the probe points.

Thank you! Is there any way to just use the data in my Gcodes instead of it auto-leveling the bed before every print?

Do you have a removable print bed?

If yes, then it's better to auto-level before every print.

Also, this 16 points are faster measured then an entire print will take.

You could modify your firmware so you do a levelling once in a while.

Bed levelling is so much hardware related, it always should belong to the printer, not the slicer.

I have the standard print bed with a removable plate magnetically held in place.

Thanks

Darrell

Thanks for your assistance!