Printer: Maker Select v2.1

Sensor: 3dtouch clone from aliexpress

Firmware: Marlin 1.1.9.1

Is it frowned upon to tag the creator? @jneilliii

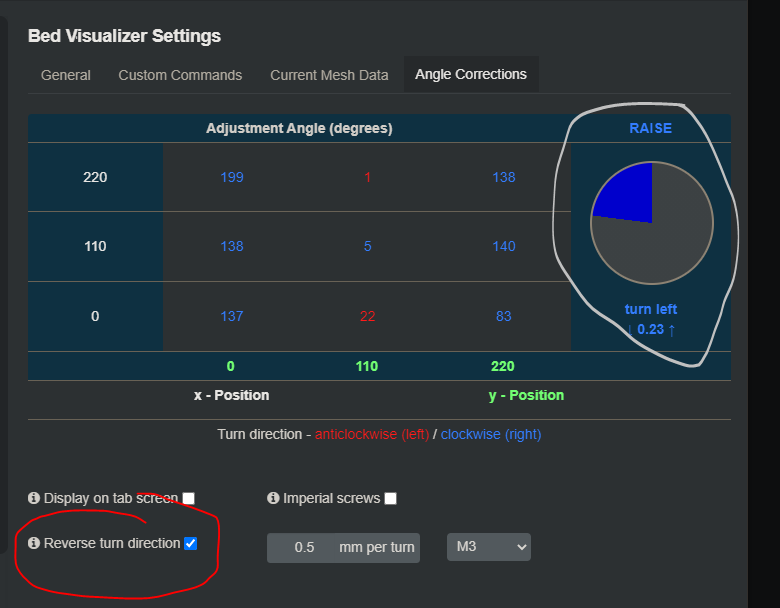

HERE are my Bed Visualizer settings for reference.

HERE is the relevant auto-level section from my Marlin config

Hello all! Longtime lurker, finally posting after I ran through tons of test runs with Bed Visualizer. So after a number my finally got my mesh visualization to look like THIS, which seems pretty good even for the weird middle kink and visualized wide v-shape it shows.

Now I've seen a lot of people reference 'Save to EEPROM', and I swear I saw that setting at one point, but now I don't see it anymore. I also read in another thread the addon's creator mention not every printer allows that so it's not there? Is that an M501 command I need to put into my GCODE?

My problem is that even with it looking like this, I still tend to get a bunch of under extrusion on one side and then the printed filament starts bunching up . Now correct me if I'm wrong, but I'm under the impression that if you run a 9-pt auto-level at the beginning of the print, the printer can use that info to make corrections during the print to account for the calculated differences. Is this true?

I have Bed Level Visualizer utilizing the following code for 'GCODE Commands for Mesh Update Process' in the 'Bed Visualizer' Settings:

M155 S30 ; set temperature reporting delay, use a value longer than the time it takes for your leveling command to complete.

@BEDLEVELVISUALIZER ; instruct plugin to start recording responses from printer.

G29 T ; report the bed leveling mesh points.

M155 S3 ; set the temperature reporting delay back to a shorter time span.

I then took some of that syntax and reused it for my 'Before print job starts' GCODE in the Octoprint settings:

M140 S65 ; set bed temp

M104 S160 ; begin preheating extruder temperature

M190 S65 ; wait for bed temp

G28 ; home all axes

@BEDLEVELVISUALIZER ; instruct plugin to start recording responses from printer.

M420 V ; ?

G29 T ; level bed & report to bed visualizer

G4 P200 ; wait 0.2 seconds

G1 X0.0 Y0.0 F2000 ; return to front left corner

G1 Z1 ; moves Z up so nozzle does not touch bed

G4 P200 ; wait 0.2 seconds

M109 S215 T0 ; wait for extruder to heat before creating purge line

G92 E0 ; zero the extruded length

G1 X50.0 F500 E25.0 ; start purge line and extrude 35mm

G92 E0 ; zero the extruded length again

Now, some of this is piecemealed together from multiple sources - some being the forums here - but I'm trying to figure out why it seems like none of this code actually takes into consideration the bed level calcualtions.

Some questions after all that info:

- Do I need to add an M500 & M501 to reset and save?

- Does adding '@BEDLEVELVISUALIZER' to Octoprint's pre-print GCODE allow for this stuff to get calculated, or do I just use G29 for that?

- Is the M420 command the one that should hypothetically take the calculations and load them for use during the print?

I appreciate any and all help and if more info is needed, please don't hesitate to ask!