Hi, first excuse my English, it's not very good.

From what I understand about your case, I think it's a bit similar to mine and I'd like to contribute some more information, in case it could help us all to find a solution.

I have a CR-10s PRO v2 printer, which I have had connected to the OctoPrint for some time now, and at the level of the system and the printer everything works apparently correctly, I have no problem sending anything to be printed from the octoprint, even through cure -> octoprint or from the APP PrintOid for Android.

However, something I was able to discover recently, thanks to a friend who also owns the same printer as me, is the following and this is where I think my case resembles yours Alphatester234:

- When the printer proceeds to print a piece that is on the SD that is inserted into the printer. The display of the printer changes from its home screen, to a screen where you can see the detail of the part that has started printing and allows you to choose printing options that can be modified while printing. However, when I order to print any piece from OctoPrint, the printer receives the print command, does the pre-heating, and all the steps until it starts printing, but the printer display's never changes from the initial screen to the screen I mentioned before when the print comes from the SD (allways stays in the screen showed after turn on and printer has startup).

Even though all the printing is done without problems when I do it from the octoprint, the printer display behaves as if it "didn't know it was printing anything", so the display doesn't change from the start screen.

The other day, by accident, I was able to reproduce a case in which the screen does change when I send a print from the Octoprint. To do this, I did the following:

1.- I sent to print a piece from the SD of the printer.

2.- The screen changed from the initial state to the screen that allows the adjustments as I said before.

3.- The printer started printing.

4.- I cancelled the printing.

5.- After confirming that I wanted to cancel the printing, once the printer has been stopped. The display has remained on the screen where it shows the detail of the print and the settings button I said before.

6 .- Being there and with nothing being printed, I have sent to print a piece from the OctoPrint.

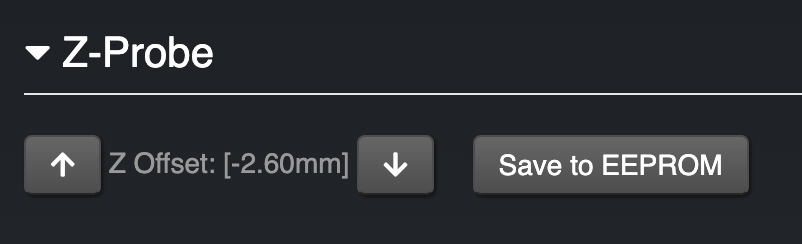

7 .- The printer receives the order for a new piece to print, the screen refreshes the data of the new piece that has begun to print and having already begun to print the new piece that comes from the octoprint and on the screen in question, I could enter the settings of the print, to modify values such as: Print speed, temperature, Z-Offset.

I thought until recently, that the fact that the printer display never changed (it only shows the current bed and hot-end temperature at the bottom of the screen) when I print something from Octoprint, was normal behaviour. However, it was because of my partner, that this is not the case... According to his printer, where he also has octoprint, the printer display should change when you print something from octoprint, just like it does when you print from the SD.

My printer is running with official firmware without any modification and OctoPrint v1.4.0