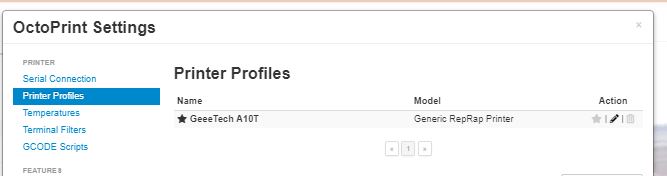

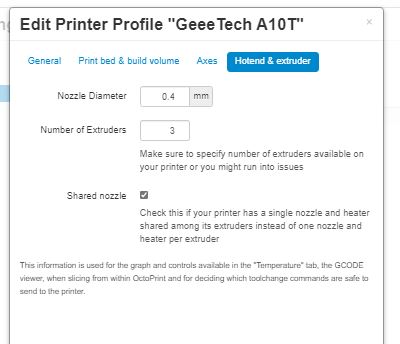

I have a GeeeTech A10T printer. This printer has three extruders but one hotend. After a recent upgrade to OctoPrint I can no longer successfully print multicolor prints with OctoPrint. I didn’t realize it immediately because I wasn’t printing multicolor prints at the time.

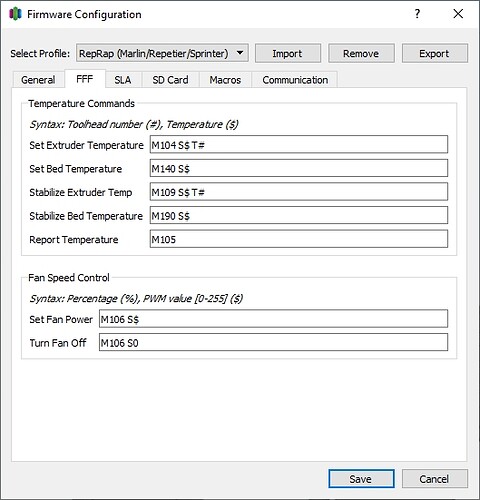

OctoPrint is updated to the latest version. The printer is running Marlin 1.1.8. I use Simplify3d, latest version as a slicer.

Prior to whatever upgrade it was, I was using GeeeTech’s color mixer to do multicolor prints, and it worked fine printing through OctoPrint.

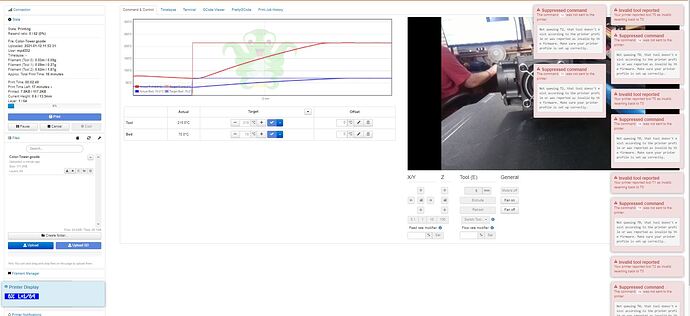

Now OctoPrint will not print multicolor prints, throwing multiple on-screen errors indicating that I have selected an invalid tool. The job prints, but it prints in a single color using whichever tool I selected as the first tool to print.

However, the job will print successfully in multicolors if I print directly from Simplify3D via a USB cable.

I’m hoping one of you smart people out there can help a dummy figure out what is going on. I’ve searched the forum and found things mentioning virtual extruders, but I haven’t got a clue how I would configure those.

The logs and screenshots are attached.

Thank you,

Kevin

WRITE HERE

What did you already try to solve it?

Searched the forum and web.

Have you tried running in safe mode?

No, safe mode doesn't support multiple extruders

Did running in safe mode solve the problem?

N/A

Complete Logs

octoprint.log, serial.log or output on terminal tab at a minimum, browser error console if UI issue ... no logs, no support! Not log excerpts, complete logs.)

WRITE HERE

Additional information about your setup

OctoPrint version, OctoPi version, printer, firmware, browser, operating system, ... as much data as possible

A10T Firmware is Marlin 1.1.8

Octoprint is 1.5.2

Browser is MS Edge

OS Is Windows 10

octoprint-Conde-01-12-21.log (717.7 KB)

serial-Conde-01-12-21.log (652.2 KB)