Okay I just did some test with the plugin

and it works good for a first attempt

but it would be good if you can implement some changes below.

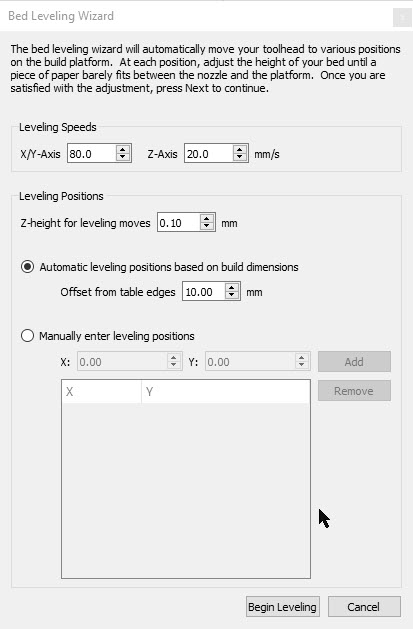

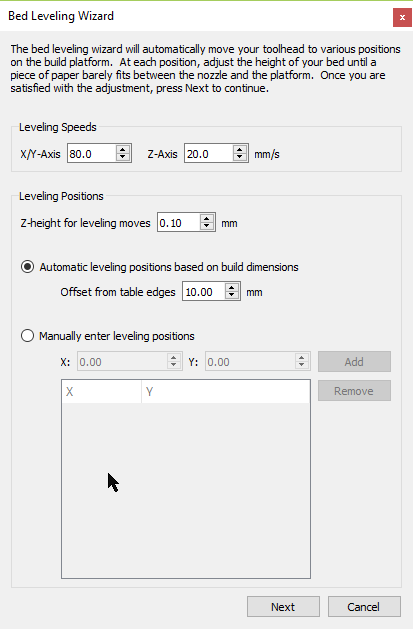

There's some differences to the S3D wizard which I think should be included

- Initially Next button should be called Start button.

This important because it will let you know that pressing the start button will take the nozzle to X/Y/Z=0

It will let the user know this will start the bed leveling procedure at Home All.

If button was always next button, then it could start procedure at the next corner which we may not remember depending on when we press the stop button or when the last corner was tested.

When you press start button, it should home all and then stop,

the start button should now be called Next. it should not move to the first corner A,

until we press the next button,

This so that some people can heat the bed up at this point before clicking next

or they may not want to start the first corner yet, but still have the nozzle home all.

- After the second time at corner D,

the Start button should be changed to Finish button when you click Next at corner D.

When you click Finish, it should raise the Z by like 20mm and then home X, Y = 0.

If there is no finish button, there is no indication of when to stop for most users.

Usually two adjustment of each corner is good enough.

When you home X/Y = 0, the finish button should be changed to start button

and the entire bed leveling procedure should reset again.

VERY IMPORTANT FIXES (else can damage printer)

-

Always begin the procedure with a Start button.

-

If you press STOP, the Next button must be changed to Start button.

and the entire bed leveling procedure must reset to the beginning.

This is important because if this is not done, and we were to move the nozzle at other locations.

when we click next again, the procedure does not know where the nozzle is, so it can try to push the nozzle beyond the bed dimensions.

This has happened when I tested it.

In S3D, when you press cancel button, the entire GUI window closes

and when you start bed leveling wizard window again, the entire procedure starts from the beginning again.

and the button is a start button (ie Begin Leveling button)

Without resetting the entire procedure, if you press next button, it will try to home the Z at the current location where the nozzle is located, and if you happen to have a bulldog clip there, then the nozzle will hit it when homing Z.

This was also observed when testing.

- There probably should be some safety precaution, when we press start button

the nozzle moves Z up by 15mm or something before homing X,Y = 0 and then Z = 0

The reason is because if we happened to have the nozzle at z=0 at any location e.g. corner D, it will move the nozzle to X/Y=0 first and if there is a bulldog clip between corner D and corner A

it will hit it when it moves to corner A.

===

In general it works but I did notice some safety issue which needs to be fix else it can damage the bed or the nozzle.

The main issue is

- nozzle does not know it's current location after you press stop button

So if you were to move the nozzle around after pressing the stop button

then press next button, the nozzle could move beyond the bed size trying go to the next corner or home Z at bad location where a bulldog clip is located.

This can be fix by resetting the entire procedure whenever user press stop button

and the next button is changed to a start button.

So when user press start button, nozzle will home all again, it is the only way that the nozzle can know where it is located again.

- There needs to be clear routine that runs only twice around the 4 corners and then resets back again.

And a start button will indicate the start of that routine and the finish button will indicate the end of that routine.

Currently there is no define beginning and ending of the bed leveling routine,

so when you press next button it will just try to go to the next corner from last corner

This is very dangerous and has been observed in testing because if you were to move the nozzle somewhere else and then press Next button, the routine will just try to go to next corner without knowing where the nozzle is located now and has tried to move the nozzle beyond the bed size (since it doesn't know where the nozzle is located) or it will hit a bulldog clip when it tries to move the next corner or home Z.

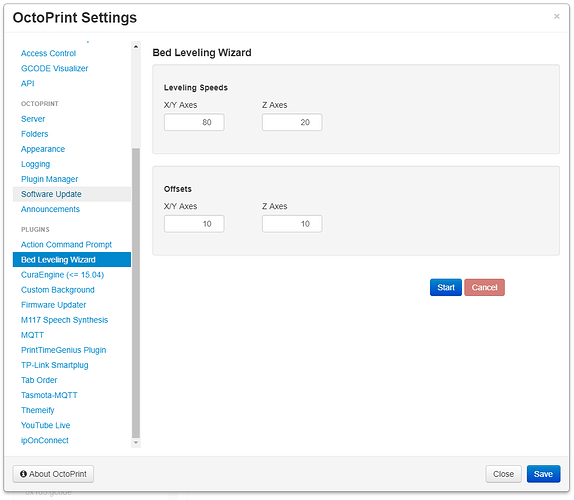

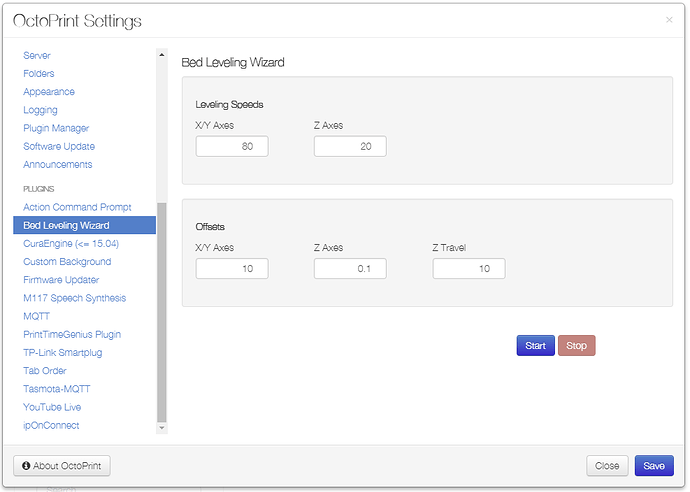

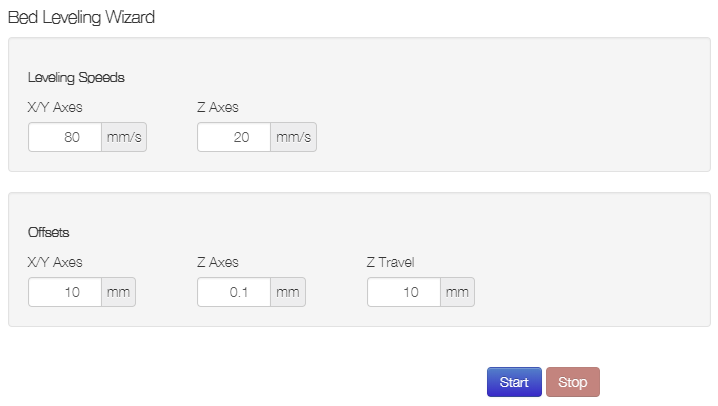

- it would also be good if you can put those settings in the side panel

It would make it easier for us to change the values instead of going through current method.

It does not look like it would take up much space on the side panel

and people can collapse it if they don't need to use bed leveling wizard.

===

These are the first major issues I observed when testing.

If you can implement the fixes mention

I can test some more to see if those problems mention still occur.