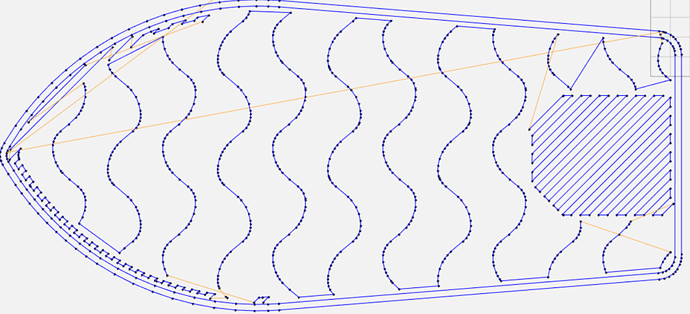

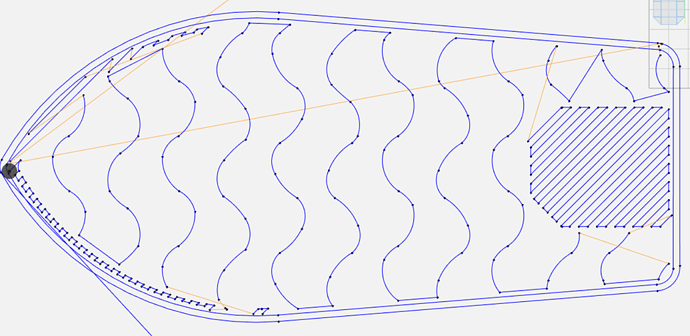

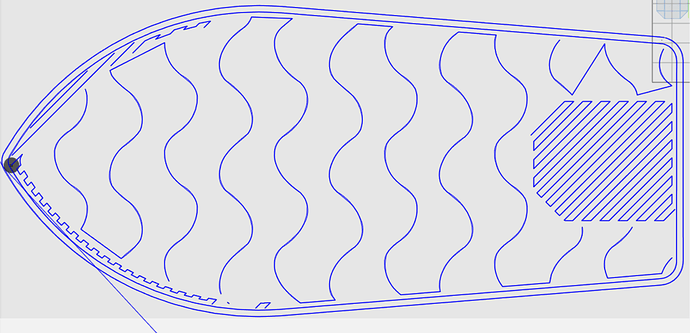

I'm looking for technically inclined users who have experienced stuttering when using OctoPrint to help me test a new plugin. Preferably the stuttering is repeatable and causes noticeable print quality issues. My plugin reduces the number of gcodes per second, and will hopefully reduce or eliminate stuttering without noticable print quality impacts.

In order to help, your printer must support G2 and G3 commands. I don't think many (any) delta printers support these, but it's pretty easy to verify by sending some G2/G3 commands via the terminal.

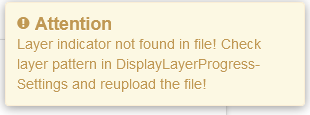

Also, there may be some installation problems because the install is rather complex and the plugin is new, so be prepared for that.

If you are interested, reply and I'll send you a DM. Thanks!

Edit: I've added the code to Github now, so the whole DM thing is moot. Here is the link to the first second third fourth pre-release from github:

https://github.com/FormerLurker/ArcWelderPlugin/archive/0.1.0rc1.dev4.zip

You can install via the plugin manager using the Get More-> ... from URL option:

Important Note: The update routine was STILL not 100% correct, so you probably will not be notified via the software update plugin. Hopefully this latest version fixes that.

If you already have the old version installed, completely uninstall and clean the files. I'm hoping installation is better behaved now that it's pulling from GitHub, but please let me know if there are any issues. If there are, please send me your plugin_pluginmanager_console.log file.

Please make sure you verify the g90/g91 influences your extruder setting (likely true if you are using stock marlin 2.0 with the stock config, false for reprap firmware), and set an appropriate resolution (it's set to 50 microns now, or 0.05mm). Don't go above 0.1mm for sure. Absolute extrusion support is newish, so that may have some undiscovered bugs. Message me if you need help with any of that.

Any issues discovered from now on should be posted to the github repository to make things easier to track.

Thanks everyone! This has been great!