Octoprint slicers aren't slicing the whole print. I tried a couple prints with the cura 15.4.X slicer plugin with the following results. then I tried the full featured slicer plugin (I guess from Octoprint?) with the same issue.

The model looks good on the slicer, but after slicing the g-code is only showing the top half of the model. As an example, if I wanted to print out a globe, I would only get the northern hemisphere in the g-code. the g-code is ignoring the bottom of the print, as a noob my estimate would be about the first 10-15 layers. I have looked into my printer profile settings and my slice profile, but like I said in the before, I'm a total noob with Octoprint.

on a side note, I have a pc at work with Cura which I have used to slice a couple stl files and those printed out beautifully, so it's gotta be somewhere between the slicer and the profiles.

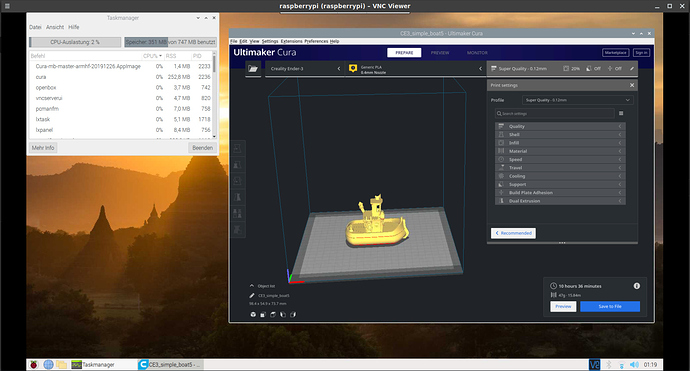

I'm using octoprint on a raspberry pi zero w, accessing it from a raspberry pi 3B+ currently, but also using linux mint Tricia

Here are the stl file and gcode rendered and my slicer profile as text since I couldn't upload it.

cable clip gcode.gco (307.7 KB) cable clip stl.stl (34.8 KB)

slicer profile

[profile]

layer_height = 0.15

wall_thickness = 1.2

retraction_enable = True

solid_layer_thickness = 1.2

fill_density = 15

print_speed = 50

print_temperature = 200

print_temperature2 = 0

print_temperature3 = 0

print_temperature4 = 0

print_temperature5 = 0

print_bed_temperature = 60

support = Everywhere

platform_adhesion = Brim

support_dual_extrusion = Both

wipe_tower = False

wipe_tower_volume = 15

ooze_shield = False

filament_diameter = 1.75

filament_diameter2 = 0

filament_diameter3 = 0

filament_diameter4 = 0

filament_diameter5 = 0

filament_flow = 100

nozzle_size = 0.4

retraction_speed = 30

retraction_amount = 6.0

retraction_dual_amount = 16.5

retraction_min_travel = 1.5

retraction_combing = All

retraction_minimal_extrusion = 0.0

retraction_hop = 0.0

bottom_thickness = 0.2

layer0_width_factor = 100

object_sink = 12

overlap_dual = 0.15

travel_speed = 60

bottom_layer_speed = 20

infill_speed = 0.0

solidarea_speed = 0.0

inset0_speed = 35

insetx_speed = 35

cool_min_layer_time = 5

fan_enabled = True

skirt_line_count = 1

skirt_gap = 3.0

skirt_minimal_length = 150.0

fan_full_height = 0.5

fan_speed = 100

fan_speed_max = 100

cool_min_feedrate = 10

cool_head_lift = False

solid_top = True

solid_bottom = True

fill_overlap = 15

perimeter_before_infill = False

support_type = Lines

support_angle = 60

support_fill_rate = 15

support_xy_distance = 0.7

support_z_distance = 0.15

spiralize = False

simple_mode = False

brim_line_count = 20

raft_margin = 5.0

raft_line_spacing = 3.0

raft_base_thickness = 0.3

raft_base_linewidth = 1.0

raft_interface_thickness = 0.27

raft_interface_linewidth = 0.4

raft_airgap_all = 0.0

raft_airgap = 0.22

raft_surface_layers = 2

raft_surface_thickness = 0.27

raft_surface_linewidth = 0.4

fix_horrible_union_all_type_a = True

fix_horrible_union_all_type_b = False

fix_horrible_use_open_bits = False

fix_horrible_extensive_stitching = False

plugin_config =

object_center_x = -1

object_center_y = -1

[alterations]

start.gcode = ;Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line

;M109 S{print_temperature} ;Uncomment to add your own temperature line

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

end.gcode = ;End GCode

M104 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

M81

;{profile_string}

start2.gcode = ;Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line

;M104 S{print_temperature} ;Uncomment to add your own temperature line

;M109 T1 S{print_temperature2} ;Uncomment to add your own temperature line

;M109 T0 S{print_temperature} ;Uncomment to add your own temperature line

G21 ;metric values

G90 ;absolute positioning

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

T1 ;Switch to the 2nd extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F200 E-{retraction_dual_amount}

T0 ;Switch to the first extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

end2.gcode = ;End GCode

M104 T0 S0 ;extruder heater off

M104 T1 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

;{profile_string}

start3.gcode = ;Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line

;M104 S{print_temperature} ;Uncomment to add your own temperature line

;M109 T1 S{print_temperature2} ;Uncomment to add your own temperature line

;M109 T0 S{print_temperature} ;Uncomment to add your own temperature line

G21 ;metric values

G90 ;absolute positioning

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

T2 ;Switch to the 3rd extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F200 E-{retraction_dual_amount}

T1 ;Switch to the 2nd extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F200 E-{retraction_dual_amount}

T0 ;Switch to the first extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

end3.gcode = ;End GCode

M104 T0 S0 ;extruder heater off

M104 T1 S0 ;extruder heater off

M104 T2 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

;{profile_string}

start4.gcode = ;Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line

;M104 S{print_temperature} ;Uncomment to add your own temperature line

;M109 T2 S{print_temperature2} ;Uncomment to add your own temperature line

;M109 T1 S{print_temperature2} ;Uncomment to add your own temperature line

;M109 T0 S{print_temperature} ;Uncomment to add your own temperature line

G21 ;metric values

G90 ;absolute positioning

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

T3 ;Switch to the 4th extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F200 E-{retraction_dual_amount}

T2 ;Switch to the 3rd extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F200 E-{retraction_dual_amount}

T1 ;Switch to the 2nd extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F200 E-{retraction_dual_amount}

T0 ;Switch to the first extruder

G92 E0 ;zero the extruded length

G1 F200 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

end4.gcode = ;End GCode

M104 T0 S0 ;extruder heater off

M104 T1 S0 ;extruder heater off

M104 T2 S0 ;extruder heater off

M104 T3 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

;{profile_string}

support_start.gcode =

support_end.gcode =

cool_start.gcode =

cool_end.gcode =

replace.csv =

preswitchextruder.gcode = ;Switch between the current extruder and the next extruder, when printing with multiple extruders.

;This code is added before the T(n)

postswitchextruder.gcode = ;Switch between the current extruder and the next extruder, when printing with multiple extruders.

;This code is added after the T(n)