Again a good hint

When connected to the tft I measured 3.3V at the sensor with pinning order like this:

V+ | GND | SIGNAL

SIGNAL is +3.3V if filament is inserted and 0V when empty.

Schematic of MKS Gen L V1.0 shows that the pins there have +5V, so I would mix up +5V from the board with +3.3V from the tft if would create a parallel connection.

So I have to disconnect the cable from TFT.

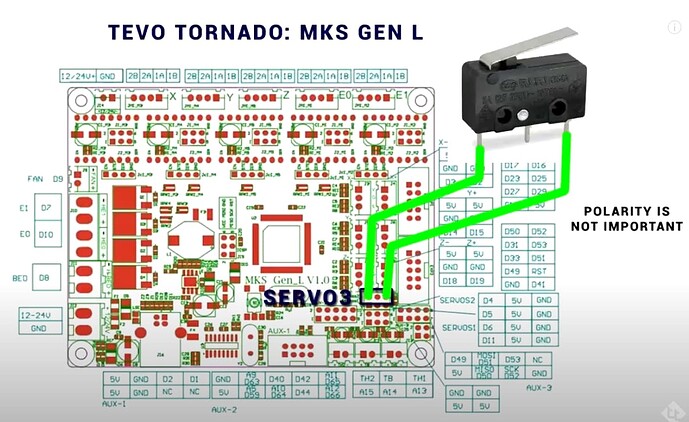

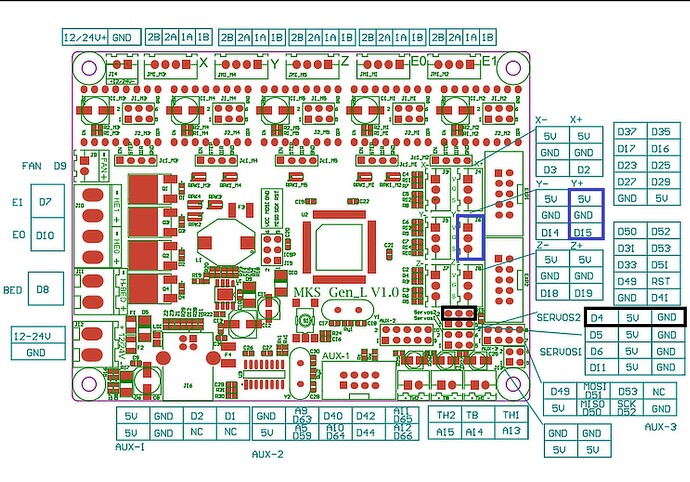

Another notice: In this video you mentioned from Teaching Tech he uses "SERVO3" which is D4 (marked black).

Unfortunately all inputs there (D4, D5, D6, D11) are already in use on my board, also +5V and GND are switched at these pins compared to the order I just measured at TFT, so I would need to switch GND / V+ in the wiring.

But instead "X+" or "Y+" on my board are free, good thing there is also that the pin order is just the same like at the tft so I can simply use the same cable only extended to reach the Y+ socket (marked blue).

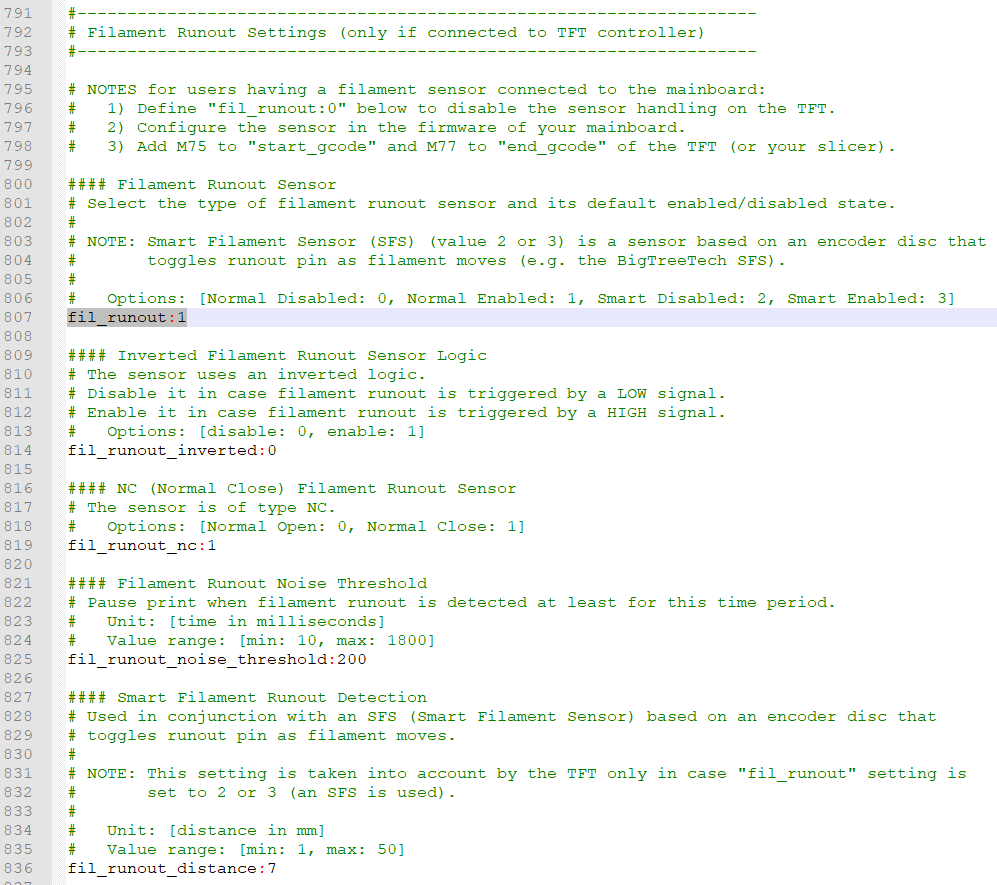

Because I now use another pin I made the following changes in the firmware:

in "pins_RAMPS.h" I changed line 286: #define FIL_RUNOUT_PIN 4 to #define FIL_RUNOUT_PIN 15 and commented out line 123: //#define Y_MAX_PIN 15 // Y+

also I prefer manual unloading for the moment so in Configuration_adv.h I changed line 2647 from #define FILAMENT_CHANGE_UNLOAD_LENGTH 100 to #define FILAMENT_CHANGE_UNLOAD_LENGTH 0.

I could not find the other two mentioned defines from the video: #define FILAMENT_CHANGE_SLOW_LOAD_LENGTH and #define FILAMENT_CHANGE_FAST_LOAD_LENGTH

After flashing that firmware I got following with pronterface:

>>> M503

SENDING:M503

echo:; Linear Units:

echo: G21 ; (mm)

echo:; Temperature Units:

echo: M149 C ; Units in Celsius

echo:; Filament settings (Disabled):

echo: M200 S0 D1.7500

echo:; Steps per unit:

echo: M92 X80.4000 Y80.4000 Z404.6500 E467.8900

echo:; Max feedrates (units/s):

echo: M203 X200.0000 Y200.0000 Z20.0000 E40.0000

echo:; Max Acceleration (units/s2):

echo: M201 X2000.0000 Y2000.0000 Z100.0000 E10000.0000

echo:; Acceleration (units/s2) (P<print-accel> R<retract-accel> T<travel-accel>):

echo: M204 P1000.0000 R10000.0000 T2000.0000

echo:; Advanced (B<min_segment_time_us> S<min_feedrate> T<min_travel_feedrate> X<max_jerk> Y<max_jerk> Z<max_jerk> E<max_jerk>):

echo: M205 B20000.0000 S0.0000 T0.0000 X8.0000 Y8.0000 Z0.3000 E10.0000

echo:; Home offset:

echo: M206 X0.0000 Y0.0000 Z0.0000

echo:; Mesh Bed Leveling:

echo: M420 S0 Z10.0000 ; Leveling OFF

echo:; Z Auto-Align:

echo: M422 S1 X10.0000 Y110.0000

echo: M422 S2 X210.0000 Y110.0000

echo:; Hotend PID:

echo: M301 P22.1896 I2.5554 D48.1709

echo:; Bed PID:

echo: M304 P24.2776 I2.9344 D133.9074

echo:; Z-Probe Offset:

echo: M851 X0.0000 Y0.0000 Z0.0000 ; (mm)

echo:; Input Shaping:

echo: M593 X F40.0000 D0.1500

echo: M593 Y F40.0000 D0.1500

echo:; Linear Advance:

echo: M900 K0.1300

echo:; Filament load/unload:

echo: M603 L0.0000 U0.0000 ; (mm)

echo:; Filament runout sensor:

echo: M412 S1 ; Sensor ON

>>> M115

SENDING:M115

FIRMWARE_NAME:Marlin 2.1.2.1 - DIGA-Tech ASWX1 v1.0 (Feb 24 2025 20:48:24) SOURCE_CODE_URL:github.com/MarlinFirmware/Marlin PROTOCOL_VERSION:1.0 MACHINE_TYPE:Artillery Genius (No Pro) EXTRUDER_COUNT:1 UUID:cede2a2f-41a2-4748-9b12-c55c62f367ff

Cap:SERIAL_XON_XOFF:0

Cap:BINARY_FILE_TRANSFER:0

Cap:EEPROM:1

Cap:VOLUMETRIC:1

Cap:AUTOREPORT_POS:1

Cap:AUTOREPORT_TEMP:1

Cap:PROGRESS:0

Cap:PRINT_JOB:1

Cap:AUTOLEVEL:0

Cap:RUNOUT:1

Cap:Z_PROBE:1

Cap:LEVELING_DATA:1

Cap:BUILD_PERCENT:1

Cap:SOFTWARE_POWER:0

Cap:TOGGLE_LIGHTS:0

Cap:CASE_LIGHT_BRIGHTNESS:0

Cap:EMERGENCY_PARSER:1

Cap:HOST_ACTION_COMMANDS:1

Cap:PROMPT_SUPPORT:1

Cap:SDCARD:0

Cap:REPEAT:0

Cap:SD_WRITE:0

Cap:AUTOREPORT_SD_STATUS:0

Cap:LONG_FILENAME:0

Cap:LFN_WRITE:0

Cap:CUSTOM_FIRMWARE_UPLOAD:0

Cap:EXTENDED_M20:0

Cap:THERMAL_PROTECTION:1

Cap:MOTION_MODES:0

Cap:ARCS:1

Cap:BABYSTEPPING:1

Cap:CHAMBER_TEMPERATURE:0

Cap:COOLER_TEMPERATURE:0

Cap:MEATPACK:0

Cap:CONFIG_EXPORT:0

area:{full:{min:{x:-3.0000,y:-3.0000,z:0.0000},max:{x:220.0000,y:220.0000,z:250.0000}},work:{min:{x:0.0000,y:0.0000,z:0.0000},max:{x:220.0000,y:220.0000,z:250.0000}}}

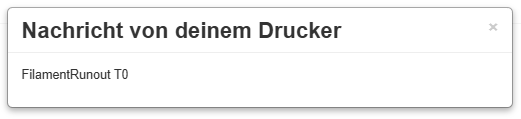

Because I saw

echo:; Filament runout sensor:

echo: M412 S1 ; Sensor ON

and

Cap:RUNOUT:1

I checked "M119":

>>> M119

SENDING:M119

Reporting endstop status

x_min: open

y_min: open

z_min: open

filament: TRIGGERED

I removed filament from the sensor and now get

>>> M119

SENDING:M119

Reporting endstop status

x_min: open

y_min: open

z_min: open

filament: open

ok P15 B3

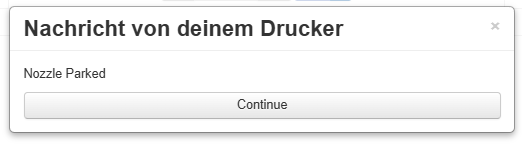

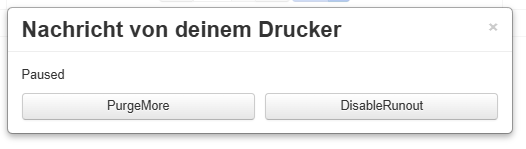

So from my perspective this is looking good and I will check a print...