What is the problem?

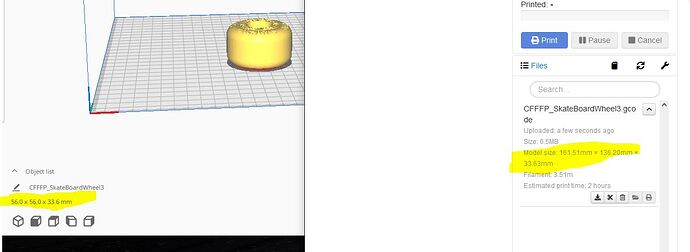

I noticed that the model size reported in Octoprint (x and y axis) is much larger than the actual model shown in Cura. The model in Cura is 56mm x 56mm x 33.6 however in Octoprint it shows 161.51mm x 136.20mm x 33.63

The model prints normally and the correct size just the size shown in the window when looking at the details in Octoprint seems way off.

What did you already try to solve it?

I re-sliced the model and re-uploaded it. No difference.

Have you tried running in safe mode?

Yes. Same dimensions shown

Did running in safe mode solve the problem?

No.

Systeminfo Bundle

You can download this in OctoPrint's System Information dialog ... no bundle, no support!)

octoprint-systeminfo-20220807203303.zip (70.4 KB)

WRITE HERE

Additional information about your setup

OctoPrint version 1.8.1, OctoPi version 0.18.0, Taz6, firmware, Firefox, Windows 10 ... as much data as possible

WRITE HERE