What is the problem?

Wired Ripples on large flat sections of prints & Print does not come out complete

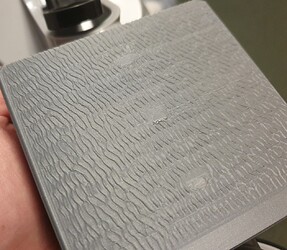

On this side only, the surface of my print came out with ripples like shown in the picture below, while all the other sides and features on the print look just fine. The Print also seemingly just stopped after about 90%, leaving the top open. I do not have a time-lapse of the print, but it seems like it actually made all the moves, considering the print head was above the edge of the part and in the park position for part removal.

checking serial.log and the gcode file I saw that the entire file should have been printed and there was no error during the printing process from what I can tell. In octoprint.log the only error I could spot was from the autoselect plugin which tried to load the .ufp file after correctly selecting the gcode file, which fails and seemingly does nothing.

After job completion I send a M150 B000 R000 U000

The Filament I am using is a completely new roll of a brand I have had luck with before, so I am guessing it is not the fault of the material im using. I also checked the nozzle for partial clogs but it seems to be really clean. The Extruder assembly seems to be intact, when I manually extrude an amount in the web interface, the right amount of filament is used, there is no skipping or any other things that would hint at a mechanical problem.

The ripples on the sides only appear on some prints, when I printed the same thing together with something else, the surface turned out smooth, but it still aborted at some 80% without any error in the logs I could see (printed at an earlier date, not in the logs, but then again, I had serial.log turned off at the time)

At this point I do not really have an idea what could be causing my problem, so I am turning to this forum

What did you already try to solve it?

- try different filament

- check logs

- upload manually just as .gcode

- update all plugins and software on host machine

Have you tried running in safe mode?

no

Complete Logs

truncated_octoprint.log (46.9 KB)

truncated_serial.log

gcode file i was printing

Additional information about your setup

browser.user_agent: Mozilla/5.0 (Windows NT 10.0; Win64; x64) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/89.0.4389.90 Safari/537.36

connectivity.connection_check: 8.8.8.8:53

connectivity.connection_ok: true

connectivity.enabled: false

connectivity.online: true

connectivity.resolution_check: octoprint.org

connectivity.resolution_ok: true

env.hardware.cores: 2

env.hardware.freq: 2200

env.hardware.ram: 3773009920

env.os.bits: 64

env.os.id: linux

env.os.platform: linux

env.python.pip: 20.1

env.python.version: 3.8.5

env.python.virtualenv: true

octoprint.safe_mode: false

octoprint.version: 1.5.3

printer.firmware: Marlin 2.0.5.1 (GitHub)