Hello

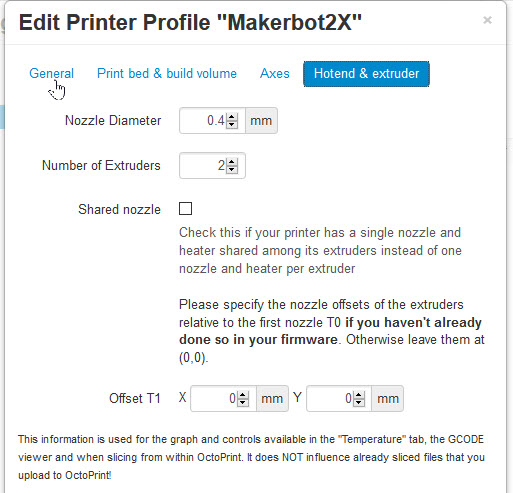

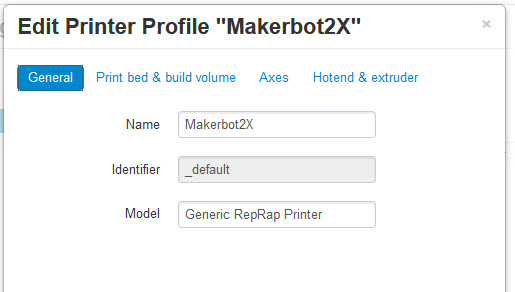

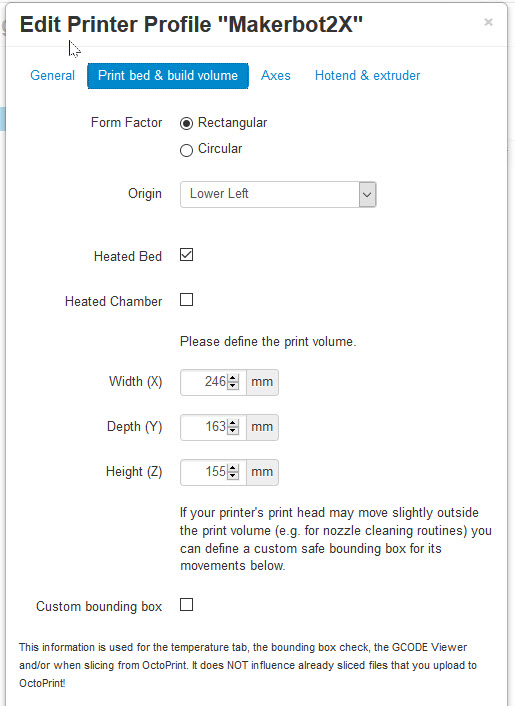

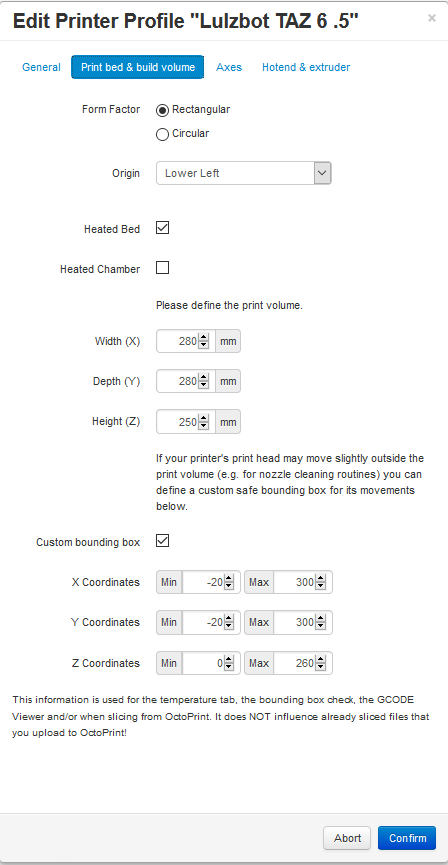

I am able to connect the Makerbot Replicator X2 to the PI (Latest version), however, the prints are always offset, the bed (Z-Axis) are not correct and it seems that Z, X, Y coordinates are not correct!

I tried to grab gCode from Simplfy3D to use before the prints..

; **** Replicator 2X start.gcode ****

M73 P0 ; Enable build progress

G162 X Y F3000 ; Home XY maximum

G161 Z F1200 ; Home Z minimum

G92 Z-5 ; Set Z to -5

G1 Z0 ; Move Z to 0

G161 Z F100 ; Home Z slowly

M132 X Y Z A B ; Recall home offsets

M135 T0 ; Load right extruder offsets

G1 X-130 Y-75 Z30 F9000 ; Move to wait position off table

G130 X20 Y20 Z20 A20 B20 ; Lower stepper Vrefs while heating

M126 S[fan_speed_pwm] ; Set fan speed

M140 S[bed0_temperature] T0 ; Heat buildplate

M134 T0 ; Stabilize bed temperature

M104 S[extruder0_temperature] T0 ; Heat right extruder

M133 T0 ; Stabilize extruder temperature

G130 X127 Y127 Z40 A127 B127 ; Default stepper Vref

G92 A0 B0 ; Zero extruders

G1 X100 Y-70 F9000 ; Move to front right corner of bed

G1 Z0.3 F6000 ; Move down to purge

G1 X-90 Y-70 E24 F2000 ; Extrude a line of filament across the front edge of the bed

G1 X-100 Y-70 F180 ; Wait for ooze

G1 X-110 Y-70 F5000 ; Fast wipe

G1 Z0.5 F100 ; Lift

G92 A0 B0 ; Zero extruders

M73 P1 ;@body (notify GPX body has started)

; **** end of start.gcode ****

What am I missing?